Fuel Energy Management

Sabina is determined to control and manage fuel energy from business operations to achieve maximum efficiency and utilization of fuel energy, which positively impacts greenhouse gas emissions from necessary fuel use. This aligns with the Sustainable Development Goals (SDGs) paradigm, specifically Goal #13 Climate Action.

Operational Goals For 2024

Reduce greenhouse gas emissions from fuel use perunit >125 Ton.CO2e (equivalent per unit sold)

- transporting store fixtures > 5.50 Ton.CO2e

- Transportation of raw materials and distribution of finished goods > 60.0 Ton.CO2e

- HR department > 13.0 Ton.CO2e

- Sales > 45 Ton.CO2e

- LPG in dyeing raw materials > 1.5 Ton.CO2e

Control Scope 1 greenhouse gas emissions not exceeding 969 Ton.Co2e or not exceeding 2% compared to 2024

- Control the use of fuel from transportation and distribution during October - December, which is the period of air pollution problems, to reduce air pollution problem by 10% compared to the first 9 months of the year to reduce pollution problems according to the time-specific target.

Performance For 2024

| Transport type | Intensity Target (Kg.CO2e) | Intensity Actual (Kg.CO2e) |

|---|---|---|

| Transport of store decoration equipment | 5.50 | 6.39 |

| Raw Material Transportation/Distribution of Finished Goods | 60.00 | 63.70 |

| HR | 13.00 | 10.80 |

| Sales | 45.00 | 52.61 |

| LPG | 1.50 | 2.56 |

| Reducing greenhouse gas emissions | 125.00 | 136.06 |

Note: Disclosure of information according to the framework GRI 305-1 Direct GHG Emission

Scope 1 greenhouse gas emissions can be controlled not exceeding 969 Ton.Co2e at 962.92 Ton.Co2e.

| GreenhouseGas Emission Type | 2023 TonCO2e | 2024 TonCO2e |

|---|---|---|

| 592.65 | 607.88 | |

| 260.46 | 264.70 | |

| 40.08 | 43.43 | |

| 50.66 | 46.90 | |

| other | 2.06 | 0 |

| Total | 949.91 | 962.92 |

Conclusion: Oil and fuel consumption of the company

| Detail | Unit | Annual | ||

|---|---|---|---|---|

| 2022 | 2023 | 2024 | ||

| diesel oil | litre | 195,819.88 | 216,764.35 | 221,808.85 |

| petrol | litre | 80,613.10 | 115,868.39 | 116,518.63 |

| LPG | kilogram | 15,309.00 | 12,875.00 | 13,950.00 |

Summarize The Company's oil and fuel consumption expenses

| Detail | Unit | Annual | ||

|---|---|---|---|---|

| 2022 | 2023 | 2024 | ||

| Oil and fuel consumption costs | baht | 12,227,490 | 14,631,556 | 14,284,934.49 |

| Percentage of oil and fuel consumption expenses to operating expenses | % | 1.20% | 1.27% | 1.19% |

| Ratio of oil and fuel consumption expenses to revenue from the sale of goods and services | Bath/Income (Thousand Baht) | 3.87 | 4.26 | 4.00 |

Energy Management

Industrial expansion has increased electricity usage, resulting in global warming and dangerous climate change such as drought, rainstorms and flooding. Additionally, rising electricity prices continually increase product costs. Therefore, the company has set goals to manage electricity for maximum benefit, as well as develop renewable energy in line with the Sustainable Development Goals (SDGs) #7 Affordable and Clean Energy. The Company has set a 5-year long-term goal to reduce electricity consumption by a third, starting from 2019, which indicated an electricity consumption of 5,798,536 kWh, i.e. a reduction goal of 33%,or 3,885,019 kWh by 2024.

Operational Goals For 2024

| Continuous Targets | Year | Electricity Consumption | Reduced Electricity Costs |

|---|---|---|---|

| 2019 | 5,798,536 | ||

| Base Year | 2023 | 4,782,461 | 23% |

| Short-term target(Compared to 2019) | 2024 | 3,885,019 | 33% |

| Medium-term Target (Compared to Base Year) | 2030 | 2,869,476 | 40% |

| Long-term Target(Compared to base Year) | 2050 | 0 | 100% |

Summary Of Operating Results Electrical Energy Management In 2024

Electricity Usage

Summary of overall electricity usage per unit of production in the foam mold department, cutting department, sewing department, and packing department. We were able to reduce electricity use per unit in 2024

Production Decreased By

Electricity Consumption Reduction

hrough the implementation of solar energy usage the company reduced electricity consumption by 23.72%, exceeding the target of 20%

with solar energy contributing 21.23% to the total consumption.

Electrical Energy Use in 2024

Water Management

Water is a resource that is important to life and activities. The company is therefore promoting access to clean water for consumption by employees in the organization and having a good sanitation system. In addition, the company realized the importance of using water for maximum benefit. Therefore, we strive to manage water in the organization, including control and management of wastewater discharged from the factory in order not to create a negative impact on the surrounding communities which is in accordance with the paradigm “Sustainable Development,” (Sustainable Development Goals-SDGs) item 6 Water and Sanitation Management.

Operational Goals For 2024

Address issues and improve water use efficiency

- Reduce overall organizational water consumption by at least 25% compared to 2023

- Reduce per capita water consumption within the organization by at least 20% compared to 2023.

Address issues and improve water use efficiency during critical periods (March, April, May) for specific locations:

- Reduce groundwater usage at Phutthamonthon Sai 5 , Chainat, and Yasothon factories by 30% compared to 2023.

- Adjust water usage processes during critical periods.

Manage wastewater

Ensure that wastewater treatment

Performance In 2024

Drinking Water Quality Inspection

Meets the standard criteria.

| Factory | Amount of water used | Effluent volume | Inspection Date | Bureau | % Pass |

|---|---|---|---|---|---|

| Phutthamonthon Sai 5 | 30,800 | 26,779 | 20/11/2024 | C.E.M. Technology Co., Ltd. | 100 |

| Tha Phra | 3,910 | 3,128 | 07/08/2024 | C.E.M. Technology Co., Ltd. | 100 |

| Chai Nat | 6,661 | 5,329 | 27/02/2024 | Test Tech Co., Ltd. | 100 |

| Yasothon | 16,777 | 13,422 | 15/3/2024 | Smile Laboratory Co., Ltd. | 100 |

| buri ram | 924 | 739 | - | - | 0 |

| office | 3,038 | 2,430 | 28/11/2024 | C.E.M. Technology Co., Ltd. | 100 |

| Total Water Consumption Unit: m³ | 62,110 | 51,827 | 98 |

Remark : Disclosure of information according to the framework GRI 303-5 Water Consumption , GRI 303-4 Water Discharge

Water Use Rate Per Person

In 2024, the average water consumption per person was 2.21 cubic meters, a decrease from 2023. and The reduction in water consumption per person reached 30%, surpassing the target of 20%.

Average Water Use Rate Per Person

The Organization's Water Use

The Organization's Water Use Amounted To

Water Consumption:3 years total of water use per person

| Water Type | 2024 | 2023 | 2022 |

|---|---|---|---|

| tap water | 32,628 | 35,999 | 25,907 |

| groundwater | 28,282 | 63,004 | 67,698 |

| Total Unit: m3 | 60,910 | 99,003 | 93,605 |

| Total of people | 3,214 | 3,488 | 3,318 |

| Total Water Consumption:People | 18.95 | 28.38 | 28.21 |

Treat Wastewater

As the company has taken various measures to take care and treat wastewater before releasing, the results of chemical residues from the company’s wastewater samples meet the standards set by the law every month.

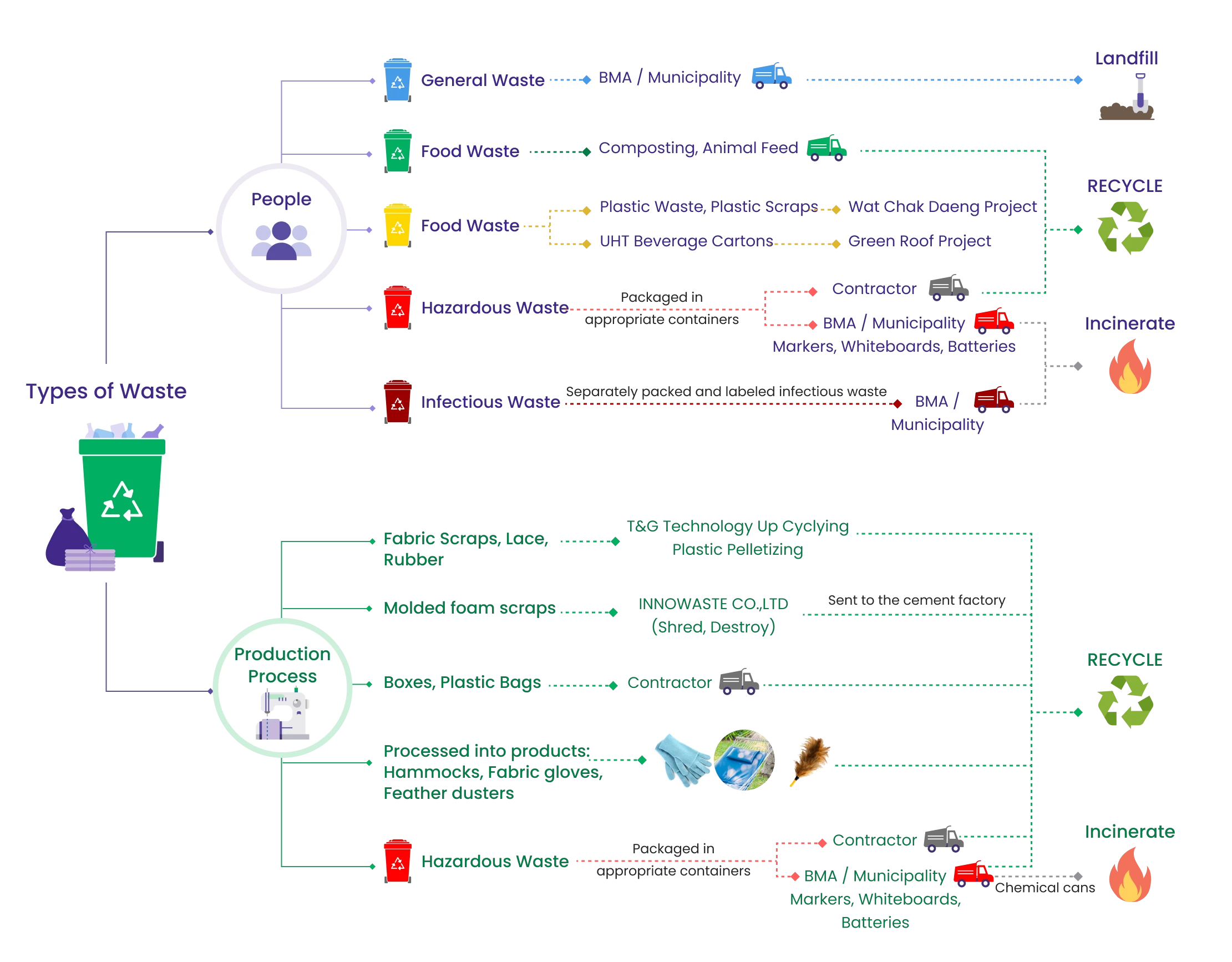

Waste Management

Solid waste creates a problem for the working environment, causes odors, is a source of disease, and may affect the health of employees and surrounding communities. The disposal of landfill waste also causes greenhouse gas emissions (1 kg = 0.842 kgCO2e), resulting in an impact on climate change. The company is aware of this problem, thus giving importance to waste management, which is the responsibility of the company. It also contributes to reducing greenhouse gas emissions.

Garbage or waste in the organization can be divided into waste caused by people and from the production process such as rags, particles, threads, and rubbers. There is waste flow as follows.

Implementation Goals For 2024

Performance In 2024

Landfill Waste And Greenhouse Gas Emissions

Reduce the amount of landfill waste and greenhouse gas emissions by

| Landfill waste 1 kg Carbon dioxide emission 0.842 kgCO2 | 2022 | 2023 | 2024 |

|---|---|---|---|

| Total landfill waste (kg) | 131,058 | 112,913 | 92,174.24 |

| Carbon dioxide emission ratio (kgCO2) | 110,351 | 95,073 | 77,611 |

| % reduction per year | (9%) | (14%) | (18%) |

| However, compared to the year 2023, the company reduced the amount of landfill waste and greenhouse gas emissions by 18% | |||

Note : Information disclosed according to GRI 305-3 other indirect GHG emissions (scope 3).

Landfill Waste Compare Sales

Reduce the amount of landfill waste Compare sales of

| Landfill waste 1 kg | 2022 | 2023 | 2024 |

|---|---|---|---|

| Total landfill waste (kg) | 131,058 | 112,913 | 92,174.24 |

| Carbon dioxide emission ratio (kgCO2) | 3,186 | 3,431 | 3,586 |

| % Compared to sales | 0.0041 | 0.0033 | 0.0026 |

| % reduction per year | (24%) | (21%) | (22%) |

| Landfill Waste Volume Compared to Sales In 2024, the company reduce landfill waste volume by 21%. | |||

Waste Recycle

Manage the waste recycle by

| Garbage type | 2022 | 2023 | 2024 | |||

|---|---|---|---|---|---|---|

| Hazardous waste | Garbage is not dangerous | Hazardous waste | Garbage is not dangerous | Hazardous waste | Garbage is not dangerous | |

| Non-recyclable waste | 131,058.00 | 112,913.00 | 1,163.24 | 91,011.00 | ||

| Recyclable waste | 17.27 | 311,562.70 | 1,000.58 | 578,835.45 | 4,962.78 | 510,143.87 |

| Total waste | 17.27 | 442,620.70 | 1,000.58 | 691,748.45 | 6,126.02 | 601,154.87 |

| % RECYCLE | 0.00% | 70.39% | 0.14% | 83.56% | 83.56% | 84.00% |

| Total waste of all types | 442,637.97 | 692,749.03 | 607,280.89 | |||

Note: In the fiscal year 2024, the performance in waste management resulted in no fines or environmental penalties.

No Complaints From The Communities About The Impact Of The Waste

There are no complaints from the communities about the impact of the waste. From the summary of the community survey on the impact of the company’s operations in Ta Phra, Phutthamonthon Sai 5, Chainat and Yasothon plant, communities were not or even slightly affected but the plant can take solution

Product Management

While the fashion industry is an industry that has the second largest negative impact on the environment in the world, Sabina, a leading lingerie manufacturer and distributor in Thailand, is therefore committed to conducting business in a sustainable manner with the following objectives:

Implementation Goals For 2024

Green Packaging

Green Uniform

Performance In 2024

In 2024, Sabina was able to create 7.17% of products from sustainable and environmentally friendly materials based on SKUs, exceeding the 5% target set.

Sustainable Products

The company successfully developed products using sustainable and environmentally friendly materials, achieving 8.53% of the total SKUs produced, surpassing the target of 8.0% Divided into two groups: Core Products and Special Collections, as follows:

-

Core Products Which Play A Significant Role And Generate Primary Revenue For The Company

1.1 Eco-friendly Bra from the Perfect Bra line, designed for large cup sizes.

In 2024, the company continued the sale of the eco-friendly Perfect Bra line, building on its introduction in 2023. The development and production of this bra reflect the company's commitment to driving business towards sustainability as follows:

- Green Foam Made from a blend containing 10% palm oil, replacing crude oil in the production process.

- TERRYL®/ECOPENT® Fabric Bio-based polyamide fiber made from renewable plant raw materials

1.2 Eco-friendly Panties from the PANTY ZONE: CLOUD ON SERIES This product line is made from TENCELTM Modal fiber fabric, a high-quality cellulose fiber derived from beech wood in Europe

1.3 Forever Young Gold Underwear Forever Young Gold stands out with its use of Bamboo Cotton Organic fabric, made from bamboo and organic cotton fibers that are grown without chemicals and toxins.

-

Collection: Products designed and produced according to seasonal trends or fashion trends.

2.1 Recycled fibers from fishing net The company launched a product for Earth Day under the special collection 'From Marine to Fashion: From the Sea to Eco-Friendly Fashion.' This was done in collaboration with the 'Nets Up' project, which transforms discarded fishing nets into 'underwear,' making it the first brand in the industry to do so.

2.2 Filagen Fibers from Fish Scales The company developed products from Filagen fibers derived from fish scales in the Top Soft Bra collection, which includes bras and underwear.

2.3 Recycled fibers from fabric scraps These recycled fibers are processed from leftover threads and fabric scraps from the production process. They are developed into high-quality recycled nylon fibers, which are then used to produce premium lace for underwear. The resulting product not only retains the beauty and elegance of the design but also reduces textile waste from the production process and promotes efficient resource utilization.

In 2023, Sabina adjusted the employee shirt fabric to TC220 which contains 65% Recycled polyester. One shirt uses 165 grams of recycled plastic. Therefore, in 2023 when 3,590 employee shirts were provided, this equaled recycling approximately 53,850 600 ml plastic bottles.

3,590 Employee shirts equaled recycling approximately 600 ml. Plastic bottles

New Life BRA-Cycle Project

Sabina Public Co., Ltd, a business leader in the production and distribution of women’s lingerie, continuously develops innovative products to meet customer’s demands in terms of design and functionality for different occasions. We also pay attention to the process of dealing with worn-out products because we believe that many people have difficulties in disposing of them and are not sure where and how to properly do so. As a result, SABINA has launched the “New Life BRA-CYCLE” campaign, which helps consumers to discard worn-out lingerie in the right way. We have begun our efforts to reduce global warming and show responsibility for the increased amount of waste we generate in the ecosystem.

Implementation Goals For 2024

Performance In 2024

Act as an intermediary in disposing of 15 tons of old undergarments within 2023. From previous operations, consumers have shown interest in participating in the Bra Disposal project by delivering worn-out undergarments to be converted into clean energy.

Act as an intermediary in disposing of

As shown in the table, a total of 14.66 tons of undergarments were collected, a slight decrease from 2022.

| Year | The underwear is torn. (Tonne) | converted to heat energy | Substitute the use of coal | Reduce carbon dioxide |

|---|---|---|---|---|

| 2022 | 15 tonne. | 331,200 MJ. | 14,720 Kg. | 24,562 Kg. |

| 2023 | 14.66 tonne. | 323,710 MJ. | 14,387 Kg. | 24,006 Kg. |

| 2024 | 15.03 tonne. | 331,879 MJ. | 14,750.23 Kg. | 24,612.36 Kg. |

| Cumulative Total | 29.66 tonne. | 654,910 MJ. | 29,107 Kg. | 48,568 Kg. |

In 2023, the amount of old underwear discarded was 14.66 tons, resulting in a reduction of approximately 24,006 kilograms of carbon dioxide emissions. The cumulative total during the 2022-2023 project period resulted in a reduction of 48,568 kgCO2e emissions.

Summary of operations in collaboration with partners to expand the scope of the "Bra-Lo" project within the supply chain, targeting 60 partners. By 2024, a total of 64 partners and organizations have expressed interest in participating in the initiative, an increase from 2023 There are 54 partners, representing an increase of 18.52%.

Number of agencies participating in activities

Greenhouse Gas Emission Control

The company is aware of greenhouse gas emissions that will have a severe impact on climate change in the future. In order to contribute to climate protection, the company conducted a Carbon Footprint for Organization (CFO) assessment to determine the amount of greenhouse gases emitted from business operations and set guidelines for reducing greenhouse gases. The company has set a strategy to reduce greenhouse gas emissions by 40% to meet the target by 2030 and achieve carbon neutrality by 2050, in line with the Sustainable Development Goals (SDGs) 9 and 13.

Performance On Greenhouse Gas Management For The Year 2024

Target comparison results

Unit: KgCo2

Note : Disclose information according to the GRI 305-5 framework to reduce the release of greenhouse gases or indirect greenhouse gases

| AssessmentYear | CertificationDate | Verifier | Greenhouse Gas Emissions Assessment Results | |||

|---|---|---|---|---|---|---|

| Scope 1 | Scope 2 | Scope 3 | CarbonSequestration | |||

| 2565 | 28/8/2566 | Bureau Veritas Certification(Thailand) | 1,012 Tonco2 | 2,112 Tonco2 | 9,799 Tonco2 | - |

| 2566 | 9/5/2567 | BSI Group (Thailand) Co., Ltd. | 950 Tonco2 | 2,391 Tonco2 | 10,069 Tonco2 | 569.36 Tonco2 |

| 2567 | PendingRegistration | BSI Group (Thailand) Co., Ltd. | 962.92 Tonco2 | 1,820.54 Tonco2 | 12,390.89 Tonco2 | 30.29 Tonco2 |

Biodiversity

The executives and employees at all levels are aware of the risks from climate change such as water scarcity, flooding, melting polar ice caps, epidemics, etc.

Performance in 2024

“Trees Planting and Biodiversity Project”

Sabina Company has therefore initiated a project to plant additional trees in the vacant areas of the factory in order to capture carbon dioxide in the trees and soil, increase clean air, and align with the executives’ commitment to achieve carbon neutrality by 2050 and support controlling global temperature rise to no more than 1.5 degrees Celsius.

Achieve carbon neutrality by 2050 and support controlling global temperature rise to no more than

Sabina Public Company Limited, Yasothon Branch, along with executives and employees, collaborated with the Yasothon Provincial Natural Resources and Environment Office and began planting trees on June 8, 2023

| Planting type(Yasothon) | Number of Trees Planted | "Amount of CO2 reduced (kg CO2)" | |

|---|---|---|---|

| 2023 | 2024(increase) | ||

| Existing plants (in the factory) | 357 | 634,309.17 | 16,893.46 |

| Existing plants (outside the factory) | 539 | 140,583.98 | - |

| Additional plants (outside the factory) | 1,736 | 20,832 | - |

| Total | 2,632 | 795,725.15 | - |

Sabina Public Company Limited, Chainat, executives and factory employees planted trees in the area.

Overall, the company The amount of plants absorbed back within the factory is 569,360 KgCo2 according to the Carbon Footprint for Organization certificate from the Greenhouse Gas Management Organization. (Public Organization)

| Planting type(Yasothon) | Number of Trees Planted | Amount of CO2 reduced (kg CO2) | |

|---|---|---|---|

| 2023 | 2024(increase) | ||

| Existing plants (in the factory) | 63 | 78,612.20 | 13,396.65 |

| Existing plants (outside the factory) | 807 | 262,119.78 | - |

| Additional plants (outside the factory) | 754 | 9,048 | - |

| Total | 1,624 | 349,779.98 | 13,396.65 |

Phutthamonthon Sai 5 Factory Executives and employees planted trees in the factory area.

| Planting type(Yasothon) | Number of Trees Planted | Amount of CO2 reduced (kg CO2) | |

|---|---|---|---|

| 2023 | 2024(increase) | ||

| Additional plants (outside the factory) | - | 0 | 13,396.65 |

| Total | - | 0 | 13,396.65 |

The company wants environmental operations and greenhouse gas management to be important priorities and to comply with international standards.

They aim to apply the knowledge gained to the company’s policies. Therefore, the company has sent employees to attend relevant training courses from both government and private institutions.

Specifically, Mr. Sitthipong Borsub has been sent to attend courses related to the environment and greenhouse gas management, in order to be able to establish guidelines for greenhouse gas management practices that align with international standards.